Sustainability Spotlight Magazine

Making the invisible visible

Making 琀栀e invisible visible

In 琀栀is report SUSTAINABILITY SPOTLIGHT | 2 Quick win 8 A more sustainability sustainable strategies cuppa from the IfM 12 Sustainability: making the invisible visible Gamifying 4 sustainability 16 Sector decarbonisation: controlled environment agriculture Driving change: Technology with Defra in pursuit of perspectives from cobalt-free the Institute for 26 batteries Manufacturing 21 24 From plastic waste to better homes in Nepal 42 Collaborating Understanding Achieving net zero in for impact industrial Scope manufacturing supply 31 3 emissions chains 36 46 *Images throughout this document are from Adobe Stock, unless otherwise credited.

SUSTAINABILITY SPOTLIGHT | 3 Secti漀渀 1: We explore how waste is one of the 昀椀rst areas manufacturing organisations should tackle. By prioritising waste reduction, organisations can build a solid foundation for broader sustainability e昀昀orts and long-term success in an increasingly eco-aware global market.

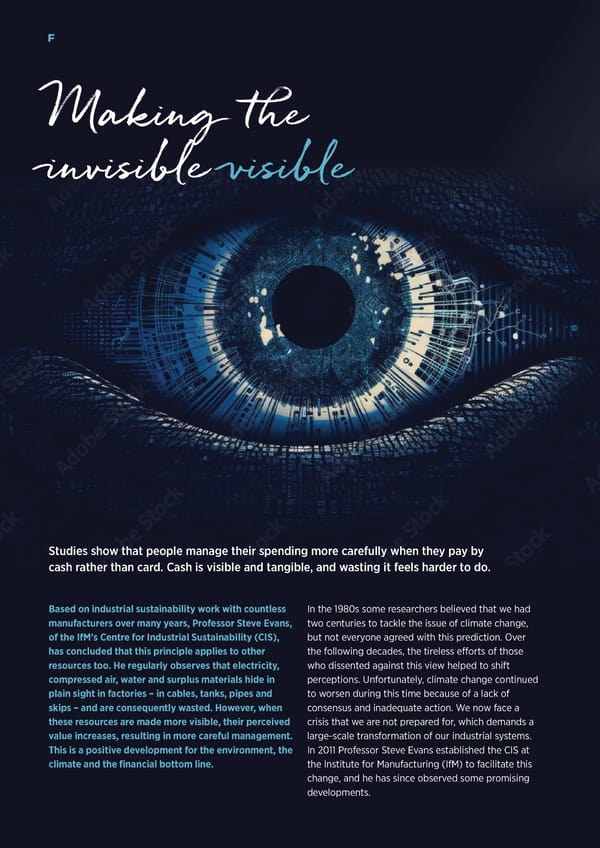

SUSTAINABILITY SPOTLIGHT | 4 Making 琀栀e invisible visible Studies show that people manage their spending more carefully when they pay by cash rather than card. Cash is visible and tangible, and wasting it feels harder to do. Based on industrial sustainability work with countless In the 1980s some researchers believed that we had manufacturers over many years, Professor Steve Evans, two centuries to tackle the issue of climate change, of the IfM’s Centre for Industrial Sustainability (CIS), but not everyone agreed with this prediction. Over has concluded that this principle applies to other the following decades, the tireless e昀昀orts of those resources too. He regularly observes that electricity, who dissented against this view helped to shift compressed air, water and surplus materials hide in perceptions. Unfortunately, climate change continued plain sight in factories – in cables, tanks, pipes and to worsen during this time because of a lack of skips – and are consequently wasted. However, when consensus and inadequate action. We now face a these resources are made more visible, their perceived crisis that we are not prepared for, which demands a value increases, resulting in more careful management. large-scale transformation of our industrial systems. This is a positive development for the environment, the In 2011 Professor Steve Evans established the CIS at climate and the 昀椀nancial bottom line. the Institute for Manufacturing (IfM) to facilitate this change, and he has since observed some promising developments.

This is a modal window.

“In even the very best companies, what was considered normal 20 years ago is now seen as absurd,” says Steve. “For example, factories would leave machines on overnight or over the weekend just to ensure the next job would be high quality. The best companies don’t do that anymore. At Toyota, an employee comes in a few hours early to ensure that the machines are operational for the shift. This practice saves them a lot of energy and money.” Examples like Toyota highlight that there is a growing focus on sustainability in industry, but many manufacturers still need convincing to change their practices, especially when they cannot see their waste. The case for industrial frugality A material world Energy waste often goes unnoticed, so it is an Manufacturing serves the purpose of producing important area of focus for Steve and his colleagues material goods for consumers, and industry has the in their work with industry. With renewable energy capacity to do so on a large scale. The sector’s history powering more than half of the electricity sold in of pollution and industry’s connection to consumerism, the UK, it is not self-evidently a sound priority, as however, may lead to the belief that manufacturing is Steve explains: “If a manufacturer exclusively relies incompatible with sustainability. This belief is incorrect on renewable energy, one might assume that there and fails to recognise that food, clothing, medicines, is little incentive for them to conserve energy, other building materials and other essential items are all than to save money. However, this is not entirely true. manufactured goods that we rely on. A sustainable Paradoxically, reducing energy consumption can be an industrial system is necessary to provide these e昀昀ective strategy to reduce real CO2 emissions. When goods to a global population of over 8 billion people. a manufacturer uses less energy, the overall energy Sustainability cannot be delivered by closing down demand in the industrial system decreases. In the UK, industry, which is good news, but we must increase our renewable energy has become cheaper to produce than innovative thinking and implement solutions. fossil fuels, so it is more likely that fossil fuel providers will be impacted by lower demand than renewable “It is hard to come up with general sustainability energy providers will. Reducing the proportion of fossil recommendations for manufacturers because they fuels in the energy mix therefore makes sense from an are so very di昀昀erent. We can’t say, ‘Do this to this economic perspective.” type of machine, do that to your schedule, do this to compressed air.’ But there is hope, because what we With a view of the whole resource system, a frugal 昀椀nd works consistently is to show people that waste is mindset is the only sensible option, according to Steve. happening. Each factory has its own toolkit for dealing Even on the materials side, there is work to be done with waste; we just need to show them that the waste is to make that change: “Material waste should not be there. We 昀椀nd that we don’t have to teach them how to the biggest challenge for manufacturers because it is identify changes that will improve the situation. They’re in their bins. You can physically see material waste if already good at that, and that is really quite important. you bother, but most people don’t bother. Even in our We must teach them how to see the waste so that they homes, waste tends to become psychologically invisible can tackle it,” says Steve. once the bin lid goes down, so we need to be told to look for it.”

SUSTAINABILITY SPOTLIGHT | 6 Examples like Toyota highlight that there is a growing focus on sustainability in industry, but many manufacturers still need convincing to change their practices, especially when they cannot see their waste. Waste is just one part of the sustainability picture “Remember the hype around Google Glasses a few in industry, but because there is so much of it, it is a years ago?” Steve muses. “Imagine putting on a pair very important part. As Steve notes, it is also an easy in a factory and getting visual access to the energy place to start when a company wants to improve its use of machines in real time, say, as a symbol that environmental impact, and making sustainability easy is changes in size according to energy spend. Such instant crucial. With good and accessible data, it is even easier. visualisation of invisible waste could be a very powerful tool.” Drawing with data Dr Duanyang Geng recently completed his PhD at the Manufacturing a sustainable world IfM, under Steve’s supervision. Duanyang has been Industrial sustainability at the IfM goes beyond the working for years to understand how industry uses data work of the eponymous CIS. From using machine to conceptualise energy waste – one of manufacturing’s learning to tackle problems of wasted space on lorries, most elusive and widespread forms of waste. For his to making sophisticated use of additive manufacturing thesis, he interviewed 30 manufacturers about their (3D printing), and helping SMEs to bene昀椀t from digital energy use, trying to establish what they perceive tracking tools, di昀昀erent groups are investing time energy waste to be and what they do to avoid it. working to manufacture a more sustainable world. In various ways, they are bringing to light what industry “There is no such thing as energy waste in nature,” and consumers overlook or ignore, providing simple says Duanyang. “Energy waste is intimately linked to solutions for improvement. human industrial practices, so it is up to us to de昀椀ne what separates energy waste from energy use. My many “Not long ago, I had a lovely email from someone who interviews informed my working de昀椀nition of energy works for a company that made some signi昀椀cant CO2 waste as whatever energy is used on top of what is and 昀椀nancial savings thanks to watching videos on strictly necessary to produce something. The invisibility our research. We have not worked with this company, of energy adds complexity here – manufacturers can’t but they were able to make big changes based on the physically see the energy they use, so they don’t higher-level principles we have observed, which say automatically know where their benchmarks are. With that there is probably more waste energy, water and digital tracking software, the kilowatt-hours, £/$ and materials in your factory than you think. Go looking. CO2 equivalents can be made visible and translatable.” This company went looking, they found areas for improvement, and they improved,” says Steve. “It can be As Duanyang observes, digital tracking software has that easy, but it still needs to be done.” real potential to help manufacturers, but it remains an underused resource, especially in small and medium- sized (SME) manufacturers. Tracking tools can provide 昀椀gures on energy use, temperature, downtime and more, which can be useful in themselves and also in creative translations.

SUSTAINABILITY SPOTLIGHT | 7 Interested in exploring how your organisation can reduce waste? Visit the IfM Engage website to get insights including reports, webinars and case studies.

SUSTAINABILITY SPOTLIGHT | 8 Quick-win sustainability strategies from the IfM Insights from the Institute for Manufacturing (IfM) show that not only are rapid sustainability improvements achievable, they can also improve the bottom line. Increasingly, sustainability is moving from a “good idea” to a necessary part of doing business. As the cost of energy and materials rises, and consumers increasingly put sustainable shopping and the environment high on their list of priorities, continuous improvements in sustainability can be the di昀昀erence between thriving or shutting up shop.

SUSTAINABILITY SPOTLIGHT | 9 For manufacturers, there is now a real opportunity to be proactive in recognising future challenges, taking decisive action and making the most of opportunities. Sustainability initiatives: As part of the association, members work with the IfM what to do and how to do it to commission new projects in areas of mutual interest. Through increasing energy and resource e昀케ciency, Topics identi昀椀ed as priority areas for the association the UK stands to gain £10 billion per year in additional include supply chain sustainability and Scope 3 pro昀椀t for manufacturers (according to research from emissions, the path to net zero and the role of digital in the IfM). However, according to Professor Steve Evans, transforming sustainability. Director of Research in Industrial Sustainability at the A recent project focused on how to achieve quick IfM, the manufacturing industry has some way to go wins in sustainability improvements. The IfM talked to achieve these targets. He says: “Around 90% of the to practitioners from a range of global manufacturing resources processed to create goods are not reaching 昀椀rms, as well as sustainable manufacturing experts, to the person for whom they are made; 50% of edible identify common success factors and best practices food is not eaten, and only about 50% full loading is in businesses that had achieved consistent, rapid achieved in freight trucks in the UK. sustainability improvements. “For manufacturers, there is now a real opportunity Small steps lead to longer-term gains to be proactive in recognising future challenges, taking decisive action and making the most of the Sustainability, when included as part of continuous opportunities that will come from a global shift towards improvement objectives, can act as a foundation sustainability. It’s a daunting task, but it’s one that for building a sustainability culture. However, it’s manufacturers should – and need to – address as the also important to note that any initiatives should be sustainability imperative continues to grow. part of a larger (long-term) sustainability agenda to avoid reverting to small improvements. “Even after a “Having agreed to pursue sustainability, maybe even step change, businesses can continue to implement setting a speci昀椀c target, for many organisations the continuous improvements to optimise the system exact pathway remains unclear. To help manufacturers and seek further sustainability improvements,” says gain clarity about both ‘what to do’ and ‘how to do it’, Steve. “Rapid sustainability improvements resulting the IfM established the Sustainability Association to from continuous improvement initiatives can create an help businesses get the support they need to progress opportunity to justify larger sustainability projects or at sustainability initiatives. least provide 昀氀exibility in the company budget.” “Manufacturing organisations want advice on the best place to start with sustainability initiatives,” Steve adds. “They want to know the best strategy for e昀昀ective returns and how to avoid common pitfalls.”

SUSTAINABILITY SPOTLIGHT | 10 Six sustainable actions you can take now 4. Start small: The IfM talked to practitioners from a range of A simple yet e昀昀ective variation is to approach teams global manufacturing 昀椀rms, as well as sustainable that can look straight away at the di昀昀erence between manufacturing experts, to identify common success energy used on good days and bad days. Teams can factors and best practices in businesses that had identify ideas and processes that have been proven achieved consistent, rapid sustainability improvements. to work as they have “been done before”. One The study revealed that using continuous improvement organisational sustainability example achieved over initiatives can be an excellent way of achieving rapid 15% in improvements remotely simply by identifying sustainability improvements, demonstrating that the and acting on performance variation in annual journey towards sustainable manufacturing doesn’t production and resource data. have to be expensive. 5. Get people involved: 1. Look at your existing resources: Wide engagement and commitment were found No organisation can improve without understanding to be the most in昀氀uential factors in achieving its current condition, so it is vital to 昀椀rst assess existing rapid improvements and a successful sustainability resources at surface level. While identifying current transformation in a company. Quick sustainability waste may seem trivial, the research shows it’s very wins can be used to seek top management buy-in important and is the 昀椀rst and most vital step towards by communicating their success in achieving cost conservation. Choose three to four priority issues savings, as well as environmental bene昀椀ts. and identify target performance dimensions such 6. Recognise e昀昀ort and success: as energy/CO2, water, waste and/or potentially one Creating a working environment that recognises and other signi昀椀cant pollution challenge for your business. rewards e昀昀orts towards sustainability improvements Not only is reducing energy consumption good for can help employees at all levels to engage with sustainability performance, it also reduces costs, so this sustainability challenges. It is critical to make alignment with key business drivers helps sustainability employees feel important and at the heart of the to quickly become mainstream. improvement process. 2. Don’t wait for a full sustainability strategy: Set realistic targets that are achievable in the short term to avoid discouragement and build con昀椀dence among employees and managers. It can help to start by Download the full report holding internal discussions on priorities and focusing on well-known issues and impact points. For example, • Discover ways manufacturers during interviews in the study, companies highlighted achieve rapid sustainability opportunities to switch processes and equipment o昀昀. improvements 3. Include sustainability KPIs: • Understand success factors What gets measured gets improved. Monitoring and barriers in progressing metrics that align with sustainability is key to driving sustainability initiatives sustainability improvements through continuous • Receive a checklist with 20 improvement. It’s enough to start small with KPIs, recommendations selecting a few that track the current sustainability to drive resource condition in a cell or facility, such as the use of e昀케ciency electricity, water, coolant or the volume of materials waste. It’s also important to share these metrics often (ideally in real time) with key stakeholders, especially on the shop 昀氀oor, so they can also seek improvements and start to drive those KPIs in the right direction.

BE A CHANGEMAKER IN SUSTAINABLE MANUFACTURING The Sustainability This is no small feat. The sustainability 昀椀eld is complex and Association is fraught with uncertainty. And the rate of change is accelerating. Organisational resistance to change can be signi昀椀cant and looking for leaders presenting a convincing case to the board can feel daunting. who want to drive That’s why we’ve started the Sustainability Association. sustainable change In collaboration with world-leading researchers in the 昀椀eld to new levels in and talented peers from di昀昀erent industries, the Sustainability their manufacturing Association provides member companies with the right knowledge, right expertise and right network organisations. to accelerate sustainable change in their organisation. FIND OUT MORE AND JOIN THE ASSOCIATION: engage.ifm.eng.cam.ac.uk/sustainability-association/

SUSTAINABILITY SPOTLIGHT | 12 A more sustainable cu瀀瀀a Driving sustainability at Kenyan tea factories The Institute for Manufacturing (IfM) Focus on the “good” days partnered with top Kenyan tea exporter Kenya is one of the world’s largest producers of tea. Eastern Produce Kenya to promote simple The sector employs over 600,000 smallholder farmers, – but e昀昀ective – energy-saving practices at supporting over 3 million people. Tea production is two tea estates located in the Nandi Hills. highly energy-intensive. For example, producing 1 kg of After just 12 months of making sustainability tea requires approximately 3–6 kWh of thermal energy – supplied mainly from wood combustion – and 0.2–0.5 relevant to their local workforce, and by kWh of electrical energy from the grid, renewable introducing straightforward energy-saving energy and diesel generators. To contextualise this, solutions, Eastern Produce Kenya has seen a running a dishwasher for 1 hour typically uses 1 kWh. reduction in energy consumption – proving that simple steps can have a big impact.

A more sustainable cu瀀瀀a In 2020 Eastern Produce Kenya (EPK), one of the weather, when more thermal energy was required to country’s largest tea producers and exporters, invited remove surface moisture from the green leaf. the IfM to apply the Cambridge Sustain 8 to help refocus its e昀昀orts on reducing the amount of energy However, when the data (on good and bad days) used at its Chemomi and Kepchomo tea factories. was analysed and correlated with the weather, they found that the factories were having good days in wet Through online meetings and workshops carried out weather and bad days in dry weather. “So, we asked over the course of 12 months, the team worked with them to come up with the key reasons why they had EPK to identify where energy could be saved and how good days,” says Gary. “And the top three reasons to make sustainability relevant and understood by the were things they could control. So, their usual mantra factory workers. about ‘it’s all about the weather’ didn’t apply.” Having established drivers for the good days, Gary and his Gary Punter, IfM Engage Industrial Associate, explains team were able to build on simple changes and include how the method (developed at the Institute for sta昀昀 in the journey. Manufacturing’s Centre for Industrial Sustainability) makes energy saving easy to understand and apply Simple steps = big impact because it aligns sustainability with business success: Some of the straightforward actions immediately “The Cambridge Sustain 8 Method is eight simple steps impacted 昀椀rewood and electricity improvements. that can be implemented over 12 months to deliver “Because fuel wood stored in the open has a high sustainability improvement with minimal investment. moisture content,” Gary explains, “we suggested First, by looking at factory data, the method identi昀椀es improving 昀椀rewood storage by expanding covered the key drivers of the factory. We then help the factory wood storage areas. Steam usage was also reduced to pick the areas where sustainability aligns with by eliminating steam leaks and cleaning dust from business success.” radiators and heat exchangers. We also helped to Gary explains that the 昀椀nal part of the method is to get develop an energy dashboard to delve further into the teams focusing on the “good” days and to discover withering and drying. opportunities to build and deliver action plans: “We “To reduce electricity, we encouraged the simple don’t focus on the problems,” says Gary, “but we ask: actions of switching o昀昀 lights and sockets and using What happened on the good days? It’s always more natural lighting instead. At Chemomi, this has reduced motivational to ask them to focus on the ‘good days’ consumption by 25%. within their data and attempt to build on these good periods, rather than solving the bad days.” “In addition, we suggested that tea reworking should Gary goes on to say that when the Sustain 8 method be minimised to avoid additional re-processing energy, asked why energy consumption was higher on some which damages KPIs, and the use of clear roo昀椀ng days than others, the explanation given was the wet sheets to use solar thermal to reduce the moisture of green leaf in the withering troughs.”

SUSTAINABILITY SPOTLIGHT | 14 After 12 months, teams reported a 15%–30% reduction “This wasn’t about us coming in and telling them what in thermal and electric energy consumption at both they need to do, then leaving. EPK had already been sites. There was also a signi昀椀cant increase in tea engaging in various energy-saving activities. This was produced per unit of fuel wood (kWh/m3). about walking alongside them, listening to them, and getting them involved. “Now, there is the controlled start-up of machines after a power outage,” says Chris Ballard, Technical Director “For example, we encouraged the leadership team to of EPK. “No machines are left idle or running when not establish their targets, to establish local improvement in use. There is also proper work output by employees teams to undertake surveys and implement their action who now understand that their work has a direct impact plans and provide recognition for all the hard work on energy savings. The shop-昀氀oor teams appreciate the involved.” load-shedding regime and no longer see it as a limiting factor in withering operations. For Fred Oberi, a drier operator at Kepchomo Factory, the changes have resulted in professional growth: “I was “We have also adopted a new way of covering 昀椀rewood motivated to get involved since I was made to realise in the yard, resulting in high 昀椀rewood utilisation that my role as a drier operator was critical in sustaining e昀케ciency compared to previous years. Data on the company’s business as opposed to how I have electrical energy use is collected from each section of been perceiving it. In addition, the awareness of energy the factory. The data is compared between all factories, saving has improved my ability to avoid wastage of highlighting ine昀케cient sections of a factory that must important resources at work and on a personal level.” be improved. Chris Ballard echoes the crucial role that the IfM “These actions have led to signi昀椀cant energy savings at played in engaging the sta昀昀: “Everything was in place both sites, and there has been an overall improvement mechanically, but the next step was to get the people in factory performance across all areas,” says Chris. involved. Crucial to this was engaging the shop-昀氀oor workers in the energy-saving plan. This worked because How many cows have we saved? they are the ones who understand the operations Gary explains that one of the key success stories has of every machine, since they are the users, and they been getting the local team engaged in the changes understand the challenges and areas for improvement. and making the sustainability gains relevant to their They are the ones who know possible areas for context. “We engaged the factory workers on their improvement, and therefore they had to own the terms and in their language. We did this by converting process 昀椀rst. energy into something recognisable: not gigajoules, but “The shop-昀氀oor teams took the project as their own and ‘How many cows can you buy with the savings?’ This not a ‘Cambridge University’ project. Engaging the sta昀昀 gave us all a laugh but e昀昀ectively equated to how much created ownership of the process and how the process energy had been saved. It brought understanding to the directly impacted their personal lives,” says Chris. room – that energy wasn’t something intangible. By the end of the project, they worked out that they had saved “We’ve been working on factory e昀케ciency for many 2,000 cows – the size of the president’s herd!” years,” Chris continues. “So, it’s not just something Gary recognises that local e昀昀orts have been mirrored that’s happened. The IfM clari昀椀ed precisely what we by a strong commitment from EPK HQ to try something should be doing, focusing on, and getting the factory new, as well as supportive managerial and technical personnel involved. leadership on the ground in Kenya: “The open and “We knew where all the problems were, but it’s getting positive culture of the Kenyan factory management intentions turned into action, which is challenging, and and factory sta昀昀, coupled with our empathy and that is where the IfM helped.” understanding of ‘real’ factory challenges and simple methodology, meant we could see impactful changes almost immediately.

SUSTAINABILITY SPOTLIGHT | 15 The future is bright By engaging the local workforce, making sustainability relevant and identifying simple steps that signi昀椀cantly reduce energy consumption, the Cambridge Method is now in use at 昀椀ve EPK sites in Nandi Hills. We have learnt Chris: “We have learnt that small actions lead to tangible and signi昀椀cant improvements and that energy saving can be achieved by involving all the personnel at that small actions the shop-昀氀oor level.” lead to tangible Gary: “Sustainability as a subject can feel large, not engaging, and doesn’t often relate to individual day jobs. What we do with our methodology is to engage and signi昀椀cant the workers on their terms and in their language. We bring it to life. improvements. “Companies that 昀椀nd they have a gap between sustainability ambition/strategy and gaining momentum/engagement with the factory shop 昀氀oor would bene昀椀t from using the tool.” Chris concludes: “Since working with the IfM, everything we implemented has been continued. Shop-昀氀oor workers now own the energy-saving culture. Some team members have now moved to other factories and Explore Cambridge are implementing these ideas in these factories. So, the Sustain 8 ideas and what we have learnt are spreading. We’re working together e昀昀ectively and committed to bringing Cambridge Sustain 8 is an our customers tea that has a minimal impact on the environment.” organisational engagement programme focused on making signi昀椀cant sustainability improvements with minimal investment. By bridging the gap between corporate objectives and sustainable practices on the factory 昀氀oor, this approach has been successfully implemented in numerous factories, yielding measurable savings within just one year of implementation.

SUSTAINABILITY SPOTLIGHT | 16 GAMIFYING sustainability Delivering worker engagement for environmental impact Raynor Foods, the 2023 British Sandwich highly innovative high-tech response linking employee Association Manufacturer of the Year, and the recognition and rewards to measurable KPIs in largest supplier of sandwiches to the NHS, sustainability performance – known as the S3 Project. has always been a leader in sustainability. In The aim of the S3 Project is to create a digital 2009 they pioneered the carbon footprinting twin factory using state-of-the-art technology to of sandwich products, and they have track carbon emissions in food manufacturing. By an extensive track record of sustainable incorporating aspects of gami昀椀cation to motivate the innovation delivering projects, including workforce, and real-time carbon monitoring, the aim is to demonstrate carbon reductions. The project has eliminating non-biodegradable plastics and three main elements: smart people, smart processes TM and smart factory. creating the Intense tomato, which cut waste and increased product life. Smart factory and smart processes To maintain this position and push the boundaries The foundations of the S3 project have already been of sustainability, Raynor Foods saw an opportunity established, with the University of Lincoln leading to tackle arguably their biggest challenge to date – much of the work. They analysed what improvements how to motivate everyone in the company, from the were needed in terms of CO2 reduction, discovered shop 昀氀oor upwards, to work towards improving its what digital tools would be needed to accomplish sustainability performance. To achieve this, Raynor these reductions, and were then involved in developing Foods, in collaboration with a consortium made up of and deploying these tools. These included a highly the Institute for Manufacturing (IfM), the University sophisticated set of sensors connected to game links of Lincoln and Software Imaging, came up with a attached to pieces of equipment or worn by employees.

SUSTAINABILITY SPOTLIGHT | 17 Because the groundwork was done by the consortium in terms of identifying technology aligned to business and sustainability needs, some impressive results are already becoming visible. The S3 Consortium have already been able to track a saving of 38 tonnes of carbon emissions though smarter processes. “As a business there are great correlations between wasted e昀昀ort, wasted time and higher emissions. Tackling overproduction, stock rotation processes and end-of-production waste were all key factors that led to the reduction,” says Tom. But Raynor Foods wants to go much further. “This is just a starting point, and we are expecting the savings to grow through gami昀椀cation. We’re aiming to be net zero by 2030, which is a deliberately ambitious target. But it’s got to be, because we’re running out of time, and if nobody starts moving the dial quite quickly, we’re all going to be in a really unpleasant place,” says Tom. Smart people and gami昀椀cation The company knew that the only way to do this was to get the entire workforce on board. “Because it’s only through an engaged workforce that we’re going to deliver these things. We want to make sustainability more relevant and personal to them. One area we hope to move the needle on is making the invisible – things One of the most impressive pieces of technology is the like CO2 emissions – visible, to motivate sta昀昀 to 昀椀nd Ultra-Wide Band Mesh, developed by Software Imaging. ways to reduce waste they can’t necessarily see,” says It is e昀昀ectively an invisible mesh that covers the entire Tom. enterprise and can locate a digital link within 5 to 10 cm. “It is e昀昀ectively the backbone of our whole project,” With the data in hand and an awareness of the changes says Tom Hollands, Innovation and Technical Director at that needed to be made, the challenge was to convey Raynor Foods. this information to the workforce in a way that would engage them on a personal level, and to encourage the “You can associate links with a piece of equipment, or behaviours and values that Raynor Foods want to live to people, or to processes. And because we 昀氀ooded the by as an organisation. whole area, and it’s got a very granular accuracy, you can do some fantastic things with the technology that To this end, they approached the IfM, part of the we’re only starting to discover now. You can add the University of Cambridge, which has been leading the links to scaled waste bins, which allow you to associate development of a gami昀椀cation programme to make the amount of waste with a process. You could also add improvements in sustainability. The system, which links to doors on room-sized fridges and freezers to allows employees to earn points that transform into a highlight if they are open,” says Tom. variety of rewards and bene昀椀ts, is the most advanced and innovative such system in the food industry. “These links enable you to geolocate people to a process. If you measure the process from a CO2e “It’s an engagement and education tool that allows performance perspective, you can assign performance us to motivate and achieve behavioural change, while to individuals and teams who work in that area, even if making the work fun and valuable for the employees” they only work in the area for 30 minutes.” explains Ergün Güngör, Research Associate at the IfM.

SUSTAINABILITY SPOTLIGHT | 18 Discovering motivating factors Creating KPIs that deliver worker engage- For the system to work, Raynor Foods 昀椀rst needed to ment and environmental impact discover the rewards that would be meaningful to their Employees can win the rewards in a variety of ways, workforce. This process involved Ergün interviewing including meeting KPIs, with performance monitored 8–10 “Sustainability Ambassadors” appointed by the by digital game links that they wear around their necks. company. This enabled him to get a good idea of areas It was important that the game be fair, inclusive and that were important to employees and then design a positive in nature so they can never lose points. And survey that was shared with the entire workforce. This at the most basic level they can gain them for simply covered a range of questions from what motivated coming to work on time. employees to what worried them and how they would like to improve themselves. Managers have emphasised how personal KPIs are linked to business KPIs, for instance energy use. “If we “A 昀氀exible work–life balance was the top motivating go into the warehouse or goods area, we incentivise factor, which came as a surprise to management people to keep the doors shut as long as possible because money had always seemed a prime concern because 80% of our energy is used in refrigeration when questions were asked on the shop 昀氀oor,” says and freezer systems,” says Tom. As a lot of energy is Ergün. “Personal development, a supportive working used in melting cheese for the company’s “croque top” environment, recognition and appreciation, and products, KPIs are also linked to that particular team to challenging and meaningful work were other important encourage more e昀케cient working practices. factors.” Linking business and personal KPIs took on added “Ergün has been brilliant in sitting down and doing signi昀椀cance during the project when Raynor Foods interviews, workshops, walkabouts and gathering data changed from being a family-owned business to an to understand everyone’s individual motivations, and employee-owned trust. “We’re all colleagues now. how the rewards can then recognise that,” says Tom. We have monthly colleague forums, which include representatives from across the business, where we “It’s not all about money. We’ve learnt that. It’s about meet up and discuss how we can improve things,” achievement, recognition, development, and wanting explains Tom. more quality time with their families, such as having holidays or trips to the zoo paid for,” says Tom. Certain This greater agency within the company has also played desires, such as dinner with the managing director, into other ways that employees can win points, such as donations to charities and even English lessons have coming up with ideas that can help the organisation’s been particularly surprising. sustainability goals. If an idea is implemented, points are then awarded according to the percentage of CO2 Armed with this information, the team went into emissions they save. Employees can also win points by workshops with management to look at ideas for the investing in themselves by taking courses, including reward and recognition systems, a process that entailed English language classes for non-native speakers to aligning budgets with the promises that could be made. help them better integrate into the company. Ideas that came out of the workshops included a dream prize ra昀툀e, which would make somebody’s Once the gami昀椀cation aspect is fully operational, there dream come true, a company-wide factory celebration will be a phone app that allows employees to log in and day, paid training and additional holidays. check their progress, CO2 savings and scores. “My feeling is that once the gami昀椀cation programme is fully deployed and people start getting recognised and rewarded, it’s going to seem like a very attractive thing to the whole workforce,” says Ergün.

SUSTAINABILITY SPOTLIGHT | 19 A voyage of discovery Becoming a “National Demonstrator” As Raynor Foods is a large organisation producing Raynor Foods are hoping to become a “National 80,000+ sandwiches a day, implementing a major Demonstrator”, highlighting how others could use the organisational transformation was bound to present combination of smart people, smart factories and smart challenges. practices to tackle their own sustainability goals. “The biggest challenge for us is obviously taking this “We have to be a microcosm of where the industry project within the live environment. It’s not a nice lab, needs to be, because we can’t do it by ourselves,” where everything is done securely and nothing goes out says Tom. “We want to inspire people to follow us, at all. How do you control that?” says Thierry Batariere, showcasing how some of the technology we’re using Senior Innovation Project Manager at Raynor Foods. can help engage the workforce.” Tom is also keen to highlight some of the challenges You can 昀椀nd out more about the project and ways to they initially faced around the use of the digital engage through their website: links, notably the negative associations with the “Big https://www.s3project.net/. Brother” practice of monitoring employee performance. “We were very careful not to call them tags, and we received comments that ‘you tag prisoners and cattle, not colleagues’,” says Tom. Sta昀昀 had a number of other concerns ranging from “Does it emit harmful radiation?” to “Does it record It’s not all about money. sound?” “Lots of questions like this came bubbling up, and we’ve It’s about achievement, done our best to address each one of those queries in a recognition, development reassuring way,” says Tom. and wanting quality time But despite the challenges, Tom and Thierry are already with family. impressed with the project and are looking forward to the full gami昀椀cation process being implemented. They’re also hoping the project will have an impact outside the workplace. Having realised that family was such an important motivating factor for the Raynor Watch the webinar Foods workforce, Ergün took steps to emphasise how issues such as climate change could a昀昀ect them Project leads from consortium personally and how adopting sustainable practices in partners, including Raynor Foods, their day-to-day lives could mitigate that. the IfM and Software Imaging, Turning carbon champions on the shop 昀氀oor into cover how the project is delivering carbon champions at home can only make everyone real-time carbon monitoring and involved a winner. motivating the workforce through demonstrating carbon reductions.

SUSTAINABILITY SPOTLIGHT | 20 Secti漀渀 2: We examine the latest technologies impacting organisations’ sustainability strategies, now and in the future.

SUSTAINABILITY SPOTLIGHT | 21 Drivingchange IN PURSUIT OF COBALT-FREE BATTERIES The increasing demand for electric vehicles Embracing a multidisciplinary approach has led to an increase in the demand for Multidisciplinary research is proving to be a game cobalt, which is used in Li-ion battery changer in advancing electrochemical energy storage cathodes. However, concerns about the research. Professor Michael de Volder, who leads the environment, ethics and the challenges IfM’s Nanomanufacturing Group, believes this approach inherent in cobalt production are motivating is paving the way for the creation of devices that can deliver quick and e昀케cient electrical energy: “When I researchers to explore alternatives. started working on batteries about 10 years ago, they Head of the Institute for Manufacturing’s seemed to be a simple set of anodes and cathodes Nanomanufacturing Group, Professor Michael plunged in an electrolyte. However, I quickly realised de Volder, sheds light on the pioneering that the simple battery schematics we learned at school e昀昀orts to eliminate cobalt from electric are deceptively simple, and the operation of a modern battery is nothing short of a chemistry and engineering vehicle batteries, o昀昀ering a glimpse into a miracle. This explains why the invention of the Li-ion more sustainable era for electric mobility. battery was awarded the Nobel Prize in 2019.”

SUSTAINABILITY SPOTLIGHT | 22 The manufacture of batteries involves many complex operations. In particular, the manufacturing processes used for the battery electrodes have a more profound impact on the battery operation than previously assumed. Michael explains: “For instance, using the same active materials on the anode and cathode, changing the manufacturing process can in昀氀uence how fast the battery can be charged or discharged and the overall energy and power density of the battery pack. More interestingly, manufacturing steps can also in昀氀uence the lifetime of the battery and, therefore, its sustainability. “However, modern batteries are such complicated ecosystems that optimising manufacturing by itself, without considering how this in昀氀uences [the] chemical and physical processes taking place, is meaningless. This is exactly what makes batteries so exciting to study – they force you to understand disciplines that engineers don’t usually engage in much.” Researchers have developed new cathode chemistries Collaborating across departments in Cambridge and that replace cobalt with nickel and manganese: “One other UK universities, and fostering partnerships with such group of materials, which the automotive industry industries and research centres, the group’s work has increasingly adopted, are lithium nickel manganese addresses the intricate challenges of advancing battery cobalt oxides (NMCs),” says Michael. “Over time, various technology. The same multidisciplinary ideology is generations of NMCs have been developed with a re昀氀ected in Michael’s research group composition, decreasing amount of Co and an increasing amount which consists of engineers, material scientists, of Ni content. In the most recent generations of these chemists and physicists. materials, up to 90% less Co is used in the cathode than the original LiCoO2 formulation that won the Nobel Challenges of cobalt-free batteries Prize.” Lithium-ion (Li-ion) batteries are the dominant However, the shift to cobalt-free cathodes comes with technology used in the manufacture of electrical a trade-o昀昀. While these cathodes are cost-e昀昀ective vehicles (EVs) because of their high energy density and more eco-friendly, they can deteriorate more and rechargeability. Therefore, research focused on quickly than their traditional counterparts, posing new battery technology plays a signi昀椀cant role in developing sustainability challenges. solutions to mitigate climate change. A shift towards electric vehicles poses a signi昀椀cant “They tend to deteriorate faster than their traditional challenge to the mining industry, particularly the counterparts,” Michael explains. “Compared to mining of crucial battery elements such as cobalt, formulations with higher Co content, these batteries nickel and manganese. Cobalt (Co), in particular, is experience quicker capacity fading, which means a cause for concern because of the environmental they need to be replaced more frequently, ultimately and ethical issues associated with mining it, including reducing their overall sustainability. This is a major unsafe working conditions, environmental pollution concern, as the reduced lifespan of the batteries and child labour. Although cobalt is necessary for leads to their disposal in land昀椀lls, which ultimately enhancing battery stability and lifespan, its high cost undermines the environmental bene昀椀ts of using cobalt- and the associated issues have prompted researchers to free cathodes.” investigate alternative cathode chemistries.

SUSTAINABILITY SPOTLIGHT | 23 While the EV industry is gradually embracing cathodes “As part of another grant, we are looking at how with lower Co content, according to Michael, either manufacturing processes a昀昀ect the lifetime of these the latest versions are not in use or their capacity is batteries. This work is sponsored by a £2 million ERC intentionally limited to slow down the degradation Consolidator Grant, on which I am the PI. This grant process because of stability concerns. looks speci昀椀cally at the development of scalable continuous processes for manufacturing better battery Balancing act: low-cobalt cathodes electrodes and bridging the so-called Valley of Death Given these challenges, the mission is to reduce cobalt between academic research and industry. These new content without compromising battery longevity. manufacturing processes impact not only battery In the spirit of multidisciplinary research, the IfM’s lifetime but also their energy and power density,” says Nanomanufacturing Group is working on a number of Michael. di昀昀erent projects with partners from around the UK. Finally, Michael’s group is part of a £14 million multi- The most signi昀椀cant project related to this research university Faraday Institution grant headed by the topic is a multi-university £22 million grant from the University of She昀케eld on the development of next- Faraday Institution, headed by Professor Clare Grey generation batteries that are entirely cobalt-free. in the Department of Chemistry. Michael leads one The group is focused on developing and optimising of the three project work packages, working with manufacturing steps to suit these new material colleagues from the University of Warwick, Imperial chemistries and aligning their performance more closely College London, Newcastle University, University with the requirements for their commercial adoption. College London, the University of Birmingham, the The group’s research 昀椀ndings will contribute to the University of Oxford, the University of She昀케eld and manufacture of batteries to help mitigate climate the University of Southampton. He explains: “We are change without creating new environmental challenges looking at degradation processes that are a result of by relying on unsustainable materials. Michael is incompatibilities between classic electrolytes and new optimistic that the landscape holds signi昀椀cant promise. cathodes with very low cobalt content. The team is “The journey towards cobalt-free batteries aligns looking at developing better cathodes and the anodes with the commitment to combat climate change and of batteries. underscores the pivotal role of advanced manufacturing in shaping a cleaner and more energy-e昀케cient landscape.”

SUSTAINABILITY SPOTLIGHT | 24 Technology perspectives Steve Evans, Director of Research in Michael de Volder, Head of the IfM’s Industrial Sustainability Nanomanufacturing Group “The 昀椀rst answer is that the most important focus “My current research focuses on the development of should be to rapidly improve what we are doing today Li-ion and other battery technologies that are likely to without buying new technology. This message shouldn’t play a very important role in climate-change mitigation, be mistaken as anti-technology; it just highlights that for instance by powering electric vehicles and storing organisations will get value from reviewing how existing renewable energy sources. technology can support meeting their sustainability goals. I’ve seen so many examples where organisations “Technology trends that will impact sustainability in this develop knowledge through this focus, making 昀椀eld are two-fold. On the one hand, we need to move them more prepared and e昀昀ective in selecting new away from battery chemistries that are unsustainable. technology solutions. Classic examples of this are the development of battery cathodes containing very little or no cobalt, “Organisations should also focus on current technology and electrolytes that do not contain any per昀氀uorinated spending plans to ensure that each purchase is as additives. On the other hand, the manufacturing energy/water/material e昀케cient as possible (and/or that processes for batteries are often energy-intensive and it allows for improvement in the future). Most of your rely on toxic solvents. Exciting new technological trends future environmental footprint is decided by existing in this area include dry processing methods that do not technology, so make sure that e昀케ciency is a key require solvents and energy-intensive drying steps. selection criterion so you make choices you are happy Finally, recycling of batteries is being studied to live with in the future. In terms of a trend that aligns more rigorously, which is critical to ensuring that with this, the best place to focus is data innovation – it batteries become a more sustainable technology for o昀昀ers the biggest sustainability improvement for the electri昀椀cation.” least cost, and technologies that support sustainability data insights are rapidly evolving.” Michael de Volder leads the IfM’s Nanomanufacturing Group, which focuses on developing scalable processes Steve Evans leads the IfM’s Sustainability Association. to arrange nanoparticles such as carbon nanotubes The association produced the “Sustainable Innovation: and graphene into well-de昀椀ned superstructures. These Quick Wins in Sustainable Manufacturing” report, may 昀椀nd application in sensors, electronics, catalysis, which recommends how organisations can improve energy storage, water puri昀椀cation and smart materials. sustainability performance quickly without investing heavily in new technologies.

SUSTAINABILITY SPOTLIGHT | 25 Technology perspectives What is 琀栀e latest technology trend 琀栀at wi氀氀 impact sustainability? Jagjit Singh Srai, Director of Research, Alexandra Brintrup, Professor in Digital and Head of the Centre for International Manufacturing and Head of the Supply Manufacturing Chain AI Lab: “Long-term technological trends show that advanced “While sustainability needs to be 昀椀rst and foremost manufacturing technologies can create innovative about a cultural shift into being comfortable with product designs by utilising new production methods. ‘less’, technological advances help this process. Within This holds great promise in terms of resource e昀케ciency. manufacturing, signi昀椀cant advances are being made with These advanced manufacturing technologies often battery technology, alternative energy sources, circular involve less aggressive processing, making them both materials and production processes – and AI. energy- and material-e昀케cient. Other technologies that Our lab’s research aims to understand and improve cover a broad spectrum of digital tools, such as AI, supply chains through the use of AI. Supply chains form blockchain and others, will enable us to gain visibility both the backbone of the global economy and, at the into demand and supply in our supply chain, allowing us same time, typically represent the largest environmental to synchronise them more e昀昀ectively. This, in turn, helps footprint of a manufacturing company. The most us to minimise waste and meet demand in the most promising advances we have made so far include Digital e昀케cient manner. Supply Chain Surveillance and Autonomous Systems. The 昀椀rst includes combining vast data sets from VAT, “Our latest research has involved the development of shipment, satellite imagery, and the web to train machine sustainable supply chain assessment tools, renewable learning algorithms to predict the existence of actors feedstock and by-product supply chain design involved in a supply chain and their sustainability frameworks, and the con昀椀guration of circular supply behaviours so that action can be taken to nudge them. chain models, spanning network design and data-driven The second area involves equipping a virtual replica modelling.” of a supply chain product or process. By automating planning, we alleviate the need for manual processes and Jag has extensive experience leading large-scale complex allow everyone to share resulting gains so they can be research projects comprising multiple stakeholders incentivised.” across industry, academia and public bodies. His research centre brings an engineering and strategic operations Alexandra Brintrup is Professor in Digital Manufacturing at the management perspective to the design, analysis and Institute for Manufacturing, where she leads the Supply Chain operation of international supply chains and the impact of AI Lab. Alexandra was the 昀椀rst researcher to empirically study advanced production and digital technologies. Through large-scale supply chains as complex adaptive networks, and major collaborations with industry (individual 昀椀rms and to examine their emergent properties, and to take a data- consortia), primarily in the healthcare and food/FMCG driven perspective to characterise their resilience, which led to sectors, his research 昀椀ndings have directly underpinned major understanding universal patterns that govern supply chains. organisational change.

SUSTAINABILITY SPOTLIGHT | 26 SECTOR decarb漀渀isati漀渀 Controlled environment agriculture with Defra Industrial sustainability experts from IfM Engage have collaborated with policy experts on a foresight study that explores future clean energy technologies and solutions for food production, commissioned by the Department for Environment, Food and Rural A昀昀airs (Defra).

SUSTAINABILITY SPOTLIGHT | 27 The study explores ways to decarbonise • Support, including from policy mechanisms, is controlled environment agriculture (CEA), so required for CEA to move forwards in a low-carbon that growers can supply high-quality locally manner. This presents a signi昀椀cant opportunity for produced food to the British market in the UK and can have a positive impact on both local and national economies. environmentally and 昀椀nancially sustainable • Measures and incentive mechanisms should be put in ways. It also provides robust 昀椀ndings to place now to facilitate the long investment horizons inform investments in CEA and the associated of CEA, typically 20–50 years. Current investments technologies and infrastructure, highlighting will impact the state of food production in 2050. that the right solutions can help CEA to Decline in numbers of CEA operations contribute to greater food security and the UK’s net-zero goal. Because of recent higher energy costs, in 2022 production from the sector reached its lowest level British agriculture comprises both traditional water since recordings began 30 years ago. But because intensive growing methods in open 昀椀elds and horticultural CEA has so many potential bene昀椀ts – among them the operations such as controlled environment agriculture ability to boost British food security and a昀昀ordability (CEA), some of which are highly energy- and carbon- – Defra recently commissioned a study on the gains, intensive. The scope of the Defra study was to explore costs, feasibility and scalability of current and future the potential to improve the sustainability credentials and industrial horticulture models. The work was carried feasibility of the latter. out by Dr Diana Khripko and Dr Samuel Short from IfM Engage, and Dr Bernhard Strauss and Dr Pantea Lot昀椀an CEA is an umbrella term covering several di昀昀erent from Camrosh. The report was published in December horticultural sub-sectors characterised by their separation 2023. of crops from the natural environment, and the ability to “Defra’s agri-food evidence programme supports the control parameters like temperature, humidity, carbon productivity, environmental sustainability, development dioxide concentrations, nutrients and light. Glasshouses of strategies to address the risks and trade-o昀昀s of and polythene tunnels are the most well-known examples, farming systems. This study was commissioned to but other types of set-ups, such as indoor and vertical provide context around opportunities and barriers farms, are emerging. to the sustainable growth and development of the CEA is high-yielding, water- and land-use e昀케cient, horticulture sector. Whilst it is clear from the report and historically allowed for cheap food production. But that there is no silver bullet, the information and data under the given geographical and climate conditions, collated and disseminated will be of great use as the the operations have a considerable energy demand and sector looks to further decarbonise, whilst facilitating an additional need for carbon dioxide. Currently in the resilience and productivity opportunities.” (Statement UK the sector predominantly runs on natural gas-based from Defra, 2023). technologies. Carbon-intensive infrastructure The 昀椀ndings suggest that CEA can contribute to greater The CEA sector has a considerable carbon footprint for food security, food a昀昀ordability and the net-zero goal its size, but the technologies it builds on do not when the following recommendations are considered: inherently yield high emissions. Over the last couple of decades, growers in CEA have overwhelmingly • Energy-e昀케ciency measures should be encouraged relied on combined heat and power (CHP) generation throughout the sector, with a focus on integrating low/ in line with established policy. CHP is an energy- zero-carbon energy supply systems into new CEA e昀케cient technology that even allows many growers builds. The necessary clean energy technologies and additional revenues from selling excess electricity to the solutions already exist and are largely proven. national grid. But deployed CHP are currently primarily fuelled by natural gas. It is also a common practice to enrich the atmosphere in the growing operations with carbon dioxide to boost photosynthesis. While

SUSTAINABILITY SPOTLIGHT | 28 it is mostly extracted from the combustion process, a “One of the key challenges in de昀椀ning energy transition great proportion is released into the atmosphere. The pathways at the sectoral level lies in the requirement for challenge, therefore, is to ensure that the energy used a systems-thinking approach. The selected approach to meet CEA demand comes from renewable energy and underpinning tools need to enable a holistic sources and that its supply is reliable. The study seeks evaluation of how altering the ecosystem, such as to clarify the current landscape of energy systems in the through incentivising a scaled-up adoption of a new sector and the requirements for deploying alternative technology, will in昀氀uence and reshape the sector as a clean energy technologies solutions, and to identify whole. A further level of complexity is given by a decarbonisation pathways and recommendations of large number of stakeholders, who have di昀昀erent how to support the transition towards more sustainable capabilities and interests that can bene昀椀t or hinder the future. transition. Consequently, formulating a methodology that fosters their buy-in to the 昀椀nal outcome by Method involving them in a multi-stage consultation process To gain a comprehensive understanding of current and was crucial for the overall success of the project.” says emerging energy technologies, as well as trends in CEA Diana. energy supply and demand, the authors conducted A broad range of technologies and solutions were expert interviews, desk-based research and a validation reviewed in the study. Energy e昀케ciency measures workshop with sector representatives, policy-makers included: and technology experts. Tools used to assess the data included: • Maintenance and operations management (enhanced • The ‘fast-start’ Strategic Roadmapping to map the routine maintenance and repair, and operations decarbonisation pathways monitoring and control systems) • The IfM’s Innovation Velocity Tool underpinned by • Equipment optimisation (e.g., high-e昀케ciency pumps the SWOT (strengths, weaknesses, opportunities and motors, high-e昀케ciency boilers, improved and threats) analysis to capture the technological, ventilation and cooling systems) economic and societal aspects of technology adoption • Building and glasshouse structure and materials • The Marginal Abatement Cost of Carbon (MACC) including system insulation, thermal screens, novel curve to help visualise the cost bene昀椀ts and emissions glazing technologies, and closed- and semi-closed savings of di昀昀erent technologies and solutions for the glasshouses) UK’s CEA sector. • Energy storage (diurnal and seasonal thermal energy storage solutions) Data used in the study was primarily retrieved from • Enhanced crop production through optimised LED Defra, the Climate Change Agreement (CCA) scheme lighting duration and wavelengths, carbon dioxide from the National Farmers Union (NFU) and from management, and selective crop breeding and publicly available documents such as academic articles, genetic modi昀椀cation. grey literature, including White Papers and government documents, and industry reports.

SUSTAINABILITY SPOTLIGHT | 29 Evaluated energy generation and conversion Attracting and encouraging CEA technology investments technologies included CHP and boilers 昀椀red by Certain CEA types, in particular indoor and vertical alternative fuels (e.g. biofuels and hydrogen), farming, are growing in popularity for investors who electrically powered technologies such as heat pumps perceive them as innovative ventures rather than and electrical boilers, heat recovery from waste heat agricultural techniques. The policy framework for sources (e.g. industrial sites) and geothermal sources. sustainable agriculture and horticulture, however, is too These technologies were assessed based on seven vague for many growers and investors to see CEA as a factors: technical feasibility; commercial safe choice. They are hesitant to take the risks involved in feasibility; environmental performance; organisational adopting novel technologies without support and policy requirements and capacity; suitability to existing guidelines in place. policy, regulatory and 昀椀scal incentives; societal value creation potential; and societal, consumer and retailer If investments are made in sustainable approaches, the acceptance. study paints a positive picture of the role that the UK CEA sector can play on the path to net zero. CEA can produce Findings 10 to 20 times as much food on the same geographical Decarbonising the energy supply footprint as traditional agriculture, and free up land Some CEA require only a tenth of the water of for rewilding and other environmentally advantageous conventional agriculture, but a great deal of energy purposes. to perform what the sun does naturally, so the key CEA can also reduce the risk of crop failure due to to more sustainable CEA lies in decarbonising the environmental in昀氀uences, and they provide thermal and electrical energy demand. The necessary consistently high yields of food. To fully reap the bene昀椀ts energy generation and conversion technologies already of decarbonisation, the authors urge action now. exist, and the report recognises that the obstacles Investment timelines in CEA are 20–50 years, so current to widespread use are overwhelmingly economic policy will in昀氀uence the state of British and political. The UK is ideally situated with access food production at the 2050 deadline for net zero. to various renewable energy to utilise necessary technology to become a major international player “This study was based on extensive interaction with the in low carbon CEA food production, so growers need industry to obtain real-world perspectives on the strong policy support to reduce the individual risks they challenges and opportunities facing the sector,” says Dr run by investing in the new infrastructure. Samuel Short. “Low-carbon technologies exist and are Clear policy needed for guidance already proven today, and we observed a willingness The report recognises that there is no one-size-昀椀ts-all in the industry to embrace transformation, but there solution to decarbonising the sector. Di昀昀erent is a considerable lack of clarity, and there are funding solutions and infrastructure is required to meet the challenges on the pathways forward. This study provides electrical and thermal energy demand of the individual insights to assist both industry and policymakers in CEA operation, and policy must re昀氀ect this need for enabling a wider deployment of low-carbon controlled 昀氀exibility and facilitate it. environment agriculture.” As an example, vertical farming requires less energy for Dr Diana Khripko continues: “One of the radical di昀昀erences heating than glasshouse-based CEA, and with a in moving away from fossil fuels towards warming climate the needs of the sector will start to a low-carbon energy system is that there is no one-size- include cooling as well as heating. Further, with the 昀椀ts-all technology or solution, not even within replacement of combustion processes there is a need one sector such as CEA. A future-proof and e昀昀ective for alternative, a昀昀ordable carbon dioxide sources. transition pathway therefore requires a strategy that is 昀氀exible enough to embrace legacy systems and existing low-carbon technologies, and potential future breakthrough innovations to align di昀昀erent industrial practices and their speci昀椀c requirements to locally available renewable energy sources.”

SUSTAINABILITY SPOTLIGHT | 30 Secti漀渀 3: We explore the latest research and activities at the IfM to help organisations and governments structure their sustainability approaches.

SUSTAINABILITY SPOTLIGHT | 31 Co氀氀aborating for impact: a roadmap towards a sustainable, healthy and resilient food system In 2022 IfM Engage was selected to support EIT Food, the world’s largest and most dynamic food innovation community, in shaping the direction of their future strategy. Supported by the European Institute of Innovation and Technology (EIT), a body of the European Union, EIT Food are working to make the food system more sustainable, healthy and trusted. The strategy informs the allocation of funding across projects related to EIT Food, an amount of nearly €180 million over 3 years from 2023 to 2025. This is the largest funding granted by EIT to one of its Knowledge and Innovation Communities, and it will be used to boost European innovation in the area of food.

SUSTAINABILITY SPOTLIGHT | 32 EIT Food wanted to get a vision and consensus from across a signi昀椀cant number and diverse range of stakeholders from across Europe on how to make progress in three priority missions: Healthier Lives Through Food; A Net Zero Food System; and Reducing Risk for a Fair & Resilient Food System. IfM Engage provided strategy support in relation to the 昀椀nal two missions in collaboration with Queen’s University Belfast. Andrew Carlin, Director of Missions and Strategic Programmes at EIT Food, highlights the range of insights they were looking to incorporate into their strategy: “We have hundreds of stakeholder organisations across Europe that we wanted to ensure were consulted and involved in how we are funding the future of food. We also wanted to make sure that we were utilising and building on existing insights from academic papers, case studies and subject-matter experts.” workshops, as well as informing the associated reports. Roadmapping was seen by EIT Food as the right Andrew says that the IfM’s help and support in approach for this challenge. Roadmapping is a strategic developing EIT’s thinking and approach to the project planning technique used extensively across industry, became most visible during the in-person workshops in government and academic organisations to bring clarity Paris. to complex problems and alignment of purpose. “The IfM’s very robust roadmapping methodology “I always felt it was possible. The question was getting helped us to turn information into insight. We were ourselves organised to do it. This is where the structure able to sift [through] and contextualise the mass of and the approach that the IfM brought came in. I always information out there to be able to grasp urgency and felt that with the right forum and the right approach, importance and the potential for societal impact. We we would be able to unlock that and move relatively were able to move from the wider picture to a narrower quickly, because the passion was there and the set of priorities and do that in a very structured way expertise was there,” says Andrew. over the course of a couple of days.” Making sense of complexity One of the aspects of IfM’s Engage process that Andrew 昀椀nds particularly valuable is “the element of IfM’s roadmapping process helped to transform the explicitly bringing choices into the strategy setting”. He available data into a manageable number of potential continues: “You’re dealing with a very complex 昀椀eld. projects and programmes that EIT Food could put its The issues can be so big that there’s almost a fear of footprint on. To facilitate this, over 100 people came saying ‘this is more important than that at this point in together in a 2-day roadmapping workshop in Paris. time.” Ahead of the workshops, IfM Engage and Queen’s The process created an environment where people University Belfast worked together with EIT Food could think about preferences and priorities for action. to bring together insights from over 350 academic “We were able to move from ‘this is all too complex, and industry publications, 250 questionnaires, 100 we don’t know where to start,’ to ‘we have to start case studies and 70 in-depth expert interviews. This somewhere and these are the things we need to start pre-work created insights and data that formed a with.” robust foundation for discussions at the roadmapping

SUSTAINABILITY SPOTLIGHT | 33 Adding a layer of sophistication and understanding As a result of the workshops, EIT Food now have a set of reports and recommendations that are shaping the strategy for the EU’s food system, not least when it comes to setting priorities for the allocation of funding. “We have a new funding framework published in September 2023, which takes a needs-based approach for the 昀椀rst time and is fundamentally di昀昀erent from how we’ve done it before.” Andrew refers to this as being “technology agnostic”. “It centres on the change and the societal impact we need to see and works backwards from there instead of the classic research funder model, which starts from pushing the technology forward. “Once you perceive yourself as an impact funder rather than an R&D funder, you open di昀昀erent possibilities for The case of regenerative agriculture answers being found in di昀昀erent places. For example, Andrew points to regenerative agriculture as an you might look towards funding the development of example of how the workshops created the right existing technologies from other sectors into the food environment for discussions on how EIT Food can sector, cutting 4 or 5 years of development time so operate most e昀昀ectively for its stakeholders. “For years that people experience the bene昀椀t much quicker,” says farmers have been seen as being the central 昀椀gures in Andrew. driving change. The assumption has been that if the right training or technology was o昀昀ered, everything Con昀椀dence and collaboration would change for the better. The project has also allowed EIT Food to “make a much more con昀椀dent kind of statement about our role,” says “The workshops gave farmers the opportunity to outline Andrew. the reality on the ground and some of the barriers they are facing. If supermarkets are tying them into 5-year EIT Food is now “an organisation that believes in the production contracts, they simply don’t have the space power of open innovation and collaboration as the key to alter crops for regenerative agriculture. However to success, and we are willing to say we’re comfortable much they may want to make changes, circumstances enough in our skin not to insist on exclusivity. We’ve prevent them. got an amazing community, an amazing network, and actually we can bring the power of that to help other “It made us realise that our job is to build an ecosystem organisations. That’s been really important for us, and around farmers that makes the change as supported it’s allowed us to present a much more open face to the and as incentivised as possible. Supermarkets need to world,” says Andrew. buy di昀昀erently, banks have to fund di昀昀erently, insurance companies have to change their policies. EIT Food are now working more closely with organisations that are explicitly engaged in the issues “Having farmers sitting in the room with somebody they are trying to solve. “The process has meant we are from a bank or a venture fund means that nobody can now closer to the needs rather than to the technology, ignore what’s being talked about. You get into the working with more NGOs and social enterprises. We’ve dialogue very, very quickly, and we all learned a huge been able to stretch the boundaries of our own network amount from having those voices in the room,” says to bring di昀昀erent perspectives in. That diversity is Andrew. hugely important in innovation,” says Andrew.

SUSTAINABILITY SPOTLIGHT | 34 As a result, they are seeing consortia building around Embracing community some of the big issues highlighted in the reports, such “We’ve become an organisation that is better able to as optimising the nutritional value of food. “We’ve welcome diverse and new perspectives on the big issues, allowed ourselves to admit some of these things are just but also to translate that into funded or co-funded really complex, and actually you need an environment actions much more quickly. But also then to connect that supports complexity, working itself out. Instead that community to other communities globally, and to of running away from it, we’re running towards it. We recognise the role of Europe and the global food system. won’t solve everything, but if over time we’re resolving some of the issues then we’ll make more impact more “The workshops were the spark that has taken that quickly and at a greater scale,” explains Andrew. collaborative approach to the next level, bringing di昀昀erent characters and di昀昀erent capabilities of di昀昀erent networks together. That’s been something we’ve driven and built on in this last year,” says Andrew. About roadmapping As a nod to this, EIT Food has joined the IfM’s Open Innovation Forum. The group aims to share best practice Roadmapping is a strategic and explore hot topics and opportunities along the food, planning technique that enables the drink and fast-moving consumer goods value streams. development and communication of strategy and innovation. For Andrew has noticed that there is a crossover in more information about the membership between EIT Food and the Open Innovation Forum, which has enabled him to get wider insights into approach, case studies, courses and organisations that they already know. downloadable templates, visit the IfM Engage website. “We’re seeing it through the eyes of the people in those businesses who are driving the open innovation practices,” says Andrew. He has found it to be a non- competitive environment where people are comfortable discussing their failures as well as their successes. “It’s all driven by shared experience and shared learning. That’s supported us in building new and enriching existing relationships with our community,” says Andrew. Andrew concludes: “We’ve emerged signi昀椀cantly stronger as an organisation, both in our sense of purpose and our ability to drive change. The process has led to a fundamentally di昀昀erent quality of attitude and behaviour, which is more open and more collaborative, where we want to work with organisations as peers, not just be at the end of a funding process.”

CAMBRIDGE SUSTAIN 8 Eight steps to sustainable, continuous business improvement Connect your key business drivers and sustainability engagement on the factory 昀氀oor Many organisations have clear, strong sustainability strategies and plans, but often fail to link these to the day-to-day reality of the factory 昀氀oor. Our methodology 昀椀lls this gap by inspiring frontline sta昀昀 to create improvement plans that resonate with their work and align them with key business drivers. This alignment is crucial for the sustained success of your sustainability initiatives. Focus on success: harness the power of ‘good days’ Our method highlights the achievements and practices that drive success on the best days in factories. This approach serves as a powerful motivational technique, increasing engagement and dedication to the project. Achieve signi昀椀cant sustainability improvements in just 12 months The initial steps of our engagement process focus on establishing a robust data collection plan, baselines and e昀昀ective KPIs to drive improvement. Within four months, there are improvement teams set up and working on action plans across the factory. The result is that notable KPI improvements have been achieved within a year across diverse cultures and sectors. “The ability to ensure that the impact on sustainable Explore how you can make performance is aligned to and drives standard business signi昀椀cant improvements in performance goals is really powerful. It is also exciting to 昀椀nd sustainability in just 8 steps: a programme that creates highly motivated workforces while reducing climate impacts.” Sustainability director, leading global fashion brand

SUSTAINABILITY SPOTLIGHT | 36 Understanding industrial Scope 3 emi猀猀i漀渀s: WHAT, WHY, HOW Although initially seen as secondary by most corporate-level standards, Scope 3 is now an important focus for corporations in the push to net zero, as new evidence points to its signi昀椀cance. Here, Cambridge Industrial Innovation Policy’s Dr David Leal-Ayala explores the meaning of Scope 3, its relevance and how businesses can approach this challenge. He draws upon the White Paper, The “No-Excuse” Opportunities to Tackle Scope 3 Emissions in Manufacturing and Value Chains, published by the World Economic Forum’s Industry Net Zero Accelerator Initiative.